Product Design:

We are highly renowned among our wide range of clients for our top-quality improvements to all technical aspects of drawing designs, including 2D files, and 3D files of the product.

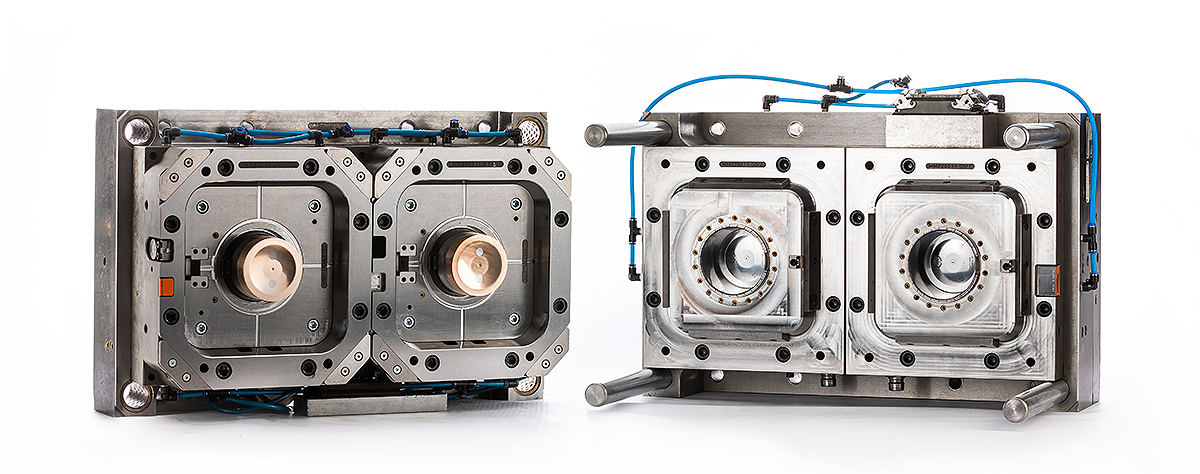

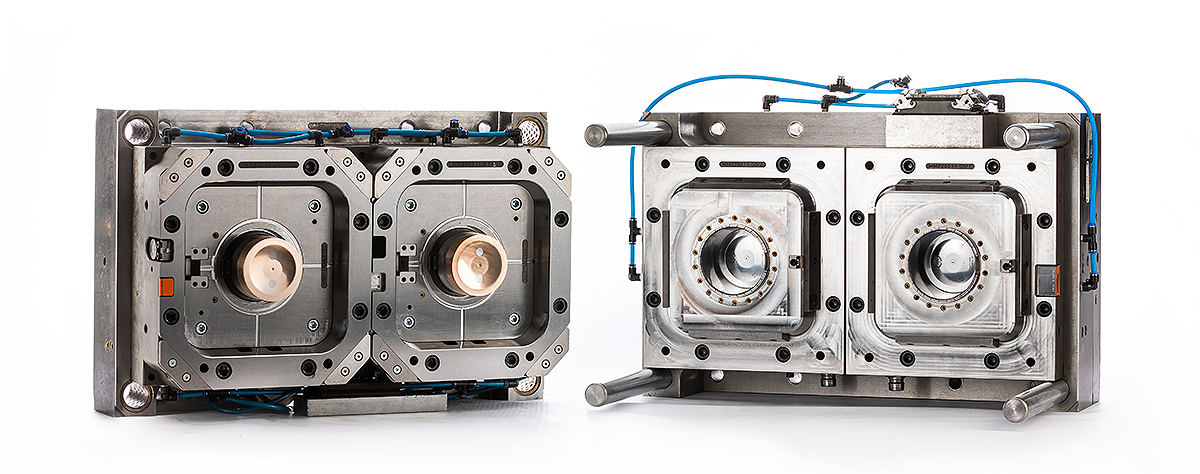

Mould Design:

This is the most critical part of the manufacturing process as it determines the life span of the mould. To prevent any errors, all of our moulds go through mould flow analysis using professional software.

Mould Manufacturing:

Our mould-manufacturing process starts with analyzing the steel. This is an essential procedure to make sure the density of the steel is accurately selected. All parts are machined by high-precision machines such as CNC high speed milling, Drilling, EDM, turning, and Engraving.

Injection Moulding:

From prototype to pilot to production parts, Eurotools and Automation combines the latest Plastic Injection Moulding processes with proper technology and an experienced Injection Moulding manufacturing team, we ensure high-quality and on-demand injection mould parts.

Food & Beverage:

- Lids, Pots, Containers, and Cups.

- Pails and buckets.

Cosmetics:

- Containers for Creams and Cosmetics Products.

- Caps, Covers, and Closures.

- Special Closing Systems.

Other Applications:

- Technical Parts.

- Medical Parts.

- Automotive Parts.